Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

Upgrade and Optimization of Automobile Interior:High Performance PVC Leather Foam Composite Fabric

Innovating technology and focusing on quality

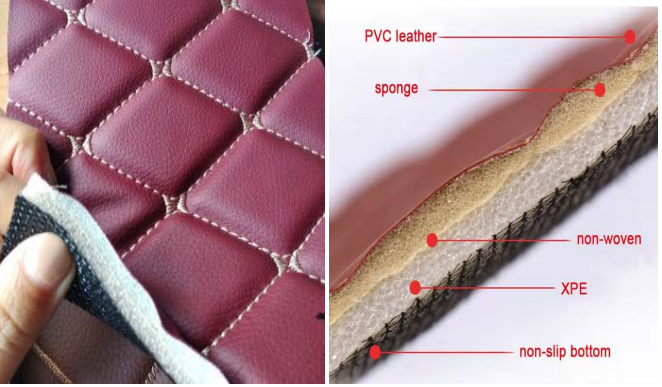

The PVC leather+foam+non-woven fabric specially developed for automobile interior is a high-end solution with both aesthetics and practicality by seamless bonding of three layers of materials through precision hot pressing technology.

The conventional thickness is 0.6 mm PVC+5 mm foam++25GSM non-woven fabric bottom, but EVA film, customized thickness, grain and sewing thread can be added as required.

Whether it is the lightweight demand of new energy vehicles or the customization project of luxury vehicles, our composite solutions have been successfully applied to the supply chain of 30+ automobile brands, helping customers shorten the development cycle and reduce production costs by more than 15%.

Core Application Scenario

Automobile seat surface layer: high wear resistance extends the service life of the seat.

Door interior trim panel: perfectly fits the curved surface design to enhance the overall texture.

Trunk lining: tear-resistant design protects valuable luggage

Center armrest/headrest: provide a comfortable touch experience

Core Advantages

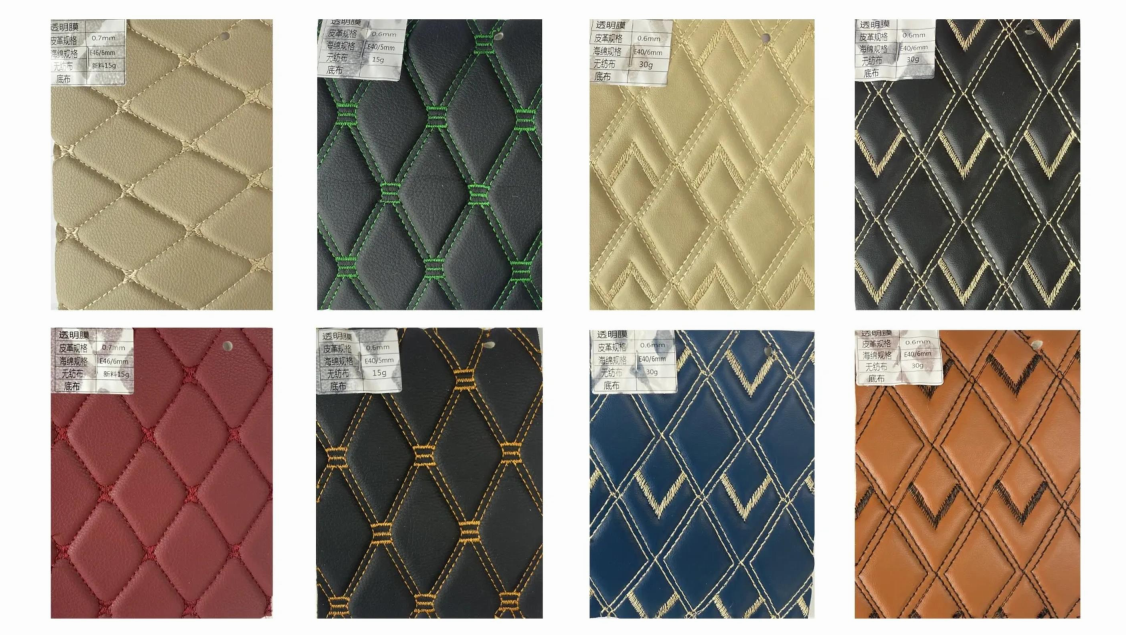

Deep customization: flexible customization in the thickness range of 1.0-3.0mm, 100+ embossing selection (litchi pattern/plain pattern/geometric pattern, etc.), full color customization, and accurate matching of automobile interior decoration scheme.

International safety certification: British standard BS5852/US CAL117 fire protection standard and FMVSS302 interior materials flame retardant standard can be customized according to requirements.

Excellent durability: anti-UV treatment ensures 5-year colorfastness (verified by ASTM G154), scratch resistance exceeds the industry standard by 200%(3H pencil hardness), and flexibility is maintained in the extreme temperature range of -40℃~80℃.

Engineering adaptability: 0.5mm tolerance control ensures assembly accuracy, and the back foam layer enhances sound insulation and shock absorption effect.

Build Your Automobile Interior Brand Benchmark

From conceptual design to mass production, we provide: scientific solutions for materials, technical support for intelligent manufacturing, and global logistics distribution system, so that innovative materials can become the competitiveness of your products. We will provide A4-size samples of materials for free so that you can check the quality!